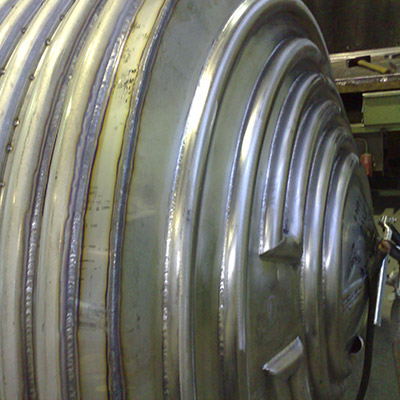

The tanks can be heated as desired in a variety of ways: thermostats, half-pipe coils, double-walled by hot water or steam.

Construction

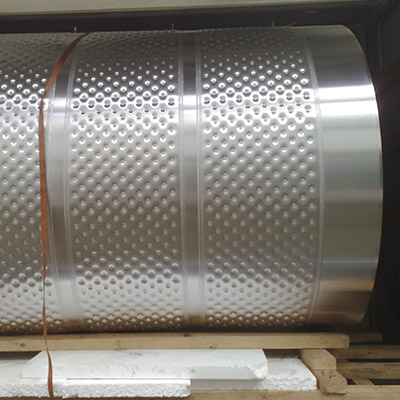

Insulation: 50 mm mineral wool lined on both sides, outer container jacket is airtightly welded. Heating: Dimple Jacket -3 bar Max. Cleaning nozzle: 2 pieces DN 25 with spray ball DN 25 (spray radius 360 °) Both in the upper cover.

Supply connection: 1 piece DN 50 in the upper cover

Outlet: 1 piece of DN 65 in the lower floor

Level measurement: over level transmitter / limit switch

Heating sockets: 8 pieces à 2 "for 4 separate heating circuits

The cooking container stands on 4 feet with foot calottes 1 "with base plate. The temperature is measured on the ground via a Pt100. All 4 heating and cooling zones can be operated separately.

Agitator: FGR ®-60 Si/A

Container pressure: atmospheric

Engine power 7,5 KW

Protection class IP 55, insulation class F

Engine model, temperature sensor (3x155 ° C), food-compatible oil according to UHSD1

Drive with flat shaft motor with hollow shaft

Agitator installation: centric from above

Agitator speed 21 rpm

Agitator shaft free-flying

Mounting flange with radial shaft seal W. St. 1.4435 Sealing NBR/>

Agitator shaft rpm. D 60 mm

Stirrer shaft length: 2.400 mm

Element: Anchor 1x 2 sheets with additional window and wall and base wiper

PTFE wipers in material PTFE / FDA material. 25% glass fiber

Product contact in W. St. 1.4435, surface sanded (Ra 1,4μm)

When the machine is turned clockwise, away from the floor and the wall. For assembly, the container cover and agitator can be removed. The cover can be folded on both sides. From one side with protection (grid)

Specifications

| Type | Tank with heating |

| Cylindrical diameter | ~ 1.700 mm |

| Height | ~ 2.800 mm |

| Outlet height | ~ 500 mm |

| Cylindrical height | ~ 2.000 mm |

| Material thickness | Inner container: 5.0 mm Outer container jacket: 3.0 mm |

| Material | Product contacting: W. St. 1.4571 otherwise 1.4301 |

New sugaring line for Fazer Finnland

Company Fazer in Finland has received a new after-treatment line (processing of confectionery) The scope of delivery included...

Read More...