Pasteurizing is one of the core elements of ten Brink. Over the decades, we have built more than 300 different pasteurisers in various designs. In the field of price / performance, we are the market leader in this sector.

The pasteurization in the water bath is still the safest and most effective way to ensure that the product in the glass has come into contact with the medium pasteurizing water / hot water and later cooling water / cold water.

The disadvantage of the water bath pasteurizer is that it requires a high energy expenditure. Large amounts of water must be circulated and tempered accordingly. In addition, the effort to build these plants is much higher and more cost intensive.

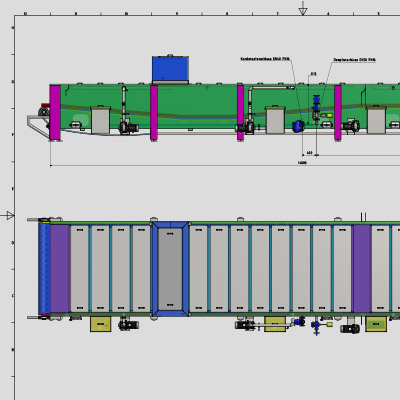

Construction

The water bath pasteurizer is produced as a self-supporting bucket construction. The covers lie loosely in the water tank. The outflow of the pasteurizing zone is sprayed from above by spraying systems. The heating pipe registers (2 pieces) are divided into "main heating and post-heating".

The tub has a one-sided slope and cleaning ducts on both sides. On the operating side, water boxes are fitted with the corresponding pumps, including piping and thermometers, pressure gauges, adjustable butterfly valves.

In the pasteurizing zone, a buffer tank is constructed in which the excess heated water from the pasteurizing zone is automatically pumped and can be re-used later, if necessary, in order to save energy.

The inlet is made of stainless steel, including 2 inspection openings. At the outlet a stainless steel extraction hood is located.

Specifications

| Type | Hot water spraying – PW 25/3,0 |

| Performance | ca. 12.780 pcs / hour |

Dimensions

| Total length including an output band | ~ 26.800 mm |

| Total width | ~ 3.650 mm |

| Total width of span | ~ 3.100 mm |

| Net width | ~ 2.990 mm |

| Height | ~ 1.800 mm |

| Working height | ~ 1.200 mm, ± 50mm |

| Usable area in the pasteurizer | ~ 75,348m² |

Drives

| Drives | SEW- geared motor 0.55 kW with frequency converter |

| Infeed tape | SEW-geared motor 0,75 kW |

| Out of band | RSEW-geared motor 0,75 kW |

Material strengths and qualities

| Tub | Stainless steel, W.St.Nr. 1.4301, 3,0 mm |

| Cover | Stainless steel, W.St.Nr. 1.4301, 1,5 mm |

| Sieving tray | Stainless steel, W.St.Nr. 1.4301, 2,5 mm |

| Frame | Stainless steel, W.St.Nr. 1.4301, 3,0 mm |

| Hot water piping | Stainless steel, W.St.Nr. 1.4571 V4a |

| Cold water piping | Stainless steel, W.St.Nr. 1.4301 |

| Curtains | Silicone rubber transparent, 2,5 mm thick |

| Sieving tray | Each 1 fixed screen (bolted) from perforated plate, hole diameter 5 mm, 2 changeover filters |

| Main transport band | Side stainless steel pull chains Tlg 76mm connected with stainless steel rollers |

| Inlet conveyer 3-lane (metal tape tape) | ~ 4.500 mm long, 2 x 114 mm VA |

| Outlet conveyor 4-lane (metal plate tape) | ~ 4.500 mm long, 3 x 114 mm VA |

| Cover | Loose in the surge tank with handles |

Heating

| 2 pcs. inner pipe registers | |

| Control 2 pcs. ball valve with control unit, 2 float separator | |

| Temperature control by 1 piece of Pt100 |

Control

| Stainless steel control cabinet completely wired. | |

| PLC System | |

| Other controls Siemens/EATON | |

| S7-200SP including visualization | |

| Touchpanel 7“with serial. Interface | |

| Switchboard type Rittal stainless steel incl. forced air fan | |

| Flashbulb (built up) | |

| Heating control via panel | |

| Incl. potential-free contacts and interface | |

| Temperature monitoring | |

| Level control | |

| Speed control main band |

Pasteurizers for Meiko

Company Meiko has received 2 new pasteurizers from ten Brink. 1 piece with a length of 30 meters...

Read More...