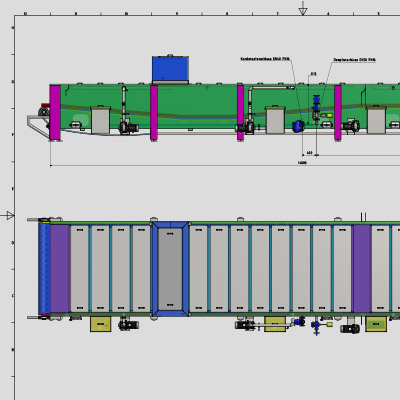

The water bath pasteurizer can be produced in various lengths and widths. In the water bath process, the packs run into a continuously adjustable water bath in the pasteurizer and cooling zone to ensure a 100% heat transfer into the products. So that the packs do not stop during the process and are always pasteurized in the same time, the main conveyor belt is equipped with drivers.

Specifications

| Type | Continuous pasteurizer with integrated cooling type water bath |

| Product | Sausages in pig's intestine |

| Weight | 90-130 grams |

| Caliber | Ø 26 - 30 mm, length about 200 mm |

| Performance | 3,000 kg / hour |

Dimensions

| Total length | ~ 26.000 mm |

| Total Width | ~ 3.000 mm |

| Useful width | 2 Spuren à 1.300 mm |

| Height | ~ 1.500 mm |

| Working height | ~ 1.100 mm, ± 50mm |

Drives

| Main drive | SEW geared motor with FI- control, interface, display of the speed in OP |

| Steam control | With 1 motor valve (Bälz) with electronic controller and digital temperature display, temperature measurement via PT 100 resistance thermometer |

Pumps

| Cooking zone 4 stainless steel pumps for sprinkling from above | Type KSB 4 kW, 230/400 V, 50 Hz |

| 2 stainless steel pumps for cooking water circulation | Type KSB 5 kW, 230/400 V, 50 Hz |

| Cooling zones 4 stainless steel pumps for sprinkling from above | Type KSB 3 kW, 230/400 V, 50 Hz |

Material strengths and qualities

| Tub | Stainless steel, W.St.Nr. 1.4301, 3,0 mm |

| Cover | Stainless steel, W.St.Nr. 1.4301, 1,5 mm |

| Sieving trays | Stainless steel, W.St.Nr. 1.4301, 2,5 mm |

| Covers | Stainless steel, W.St.Nr. 1.4301, 1,5 mm |

| Hot water piping | Stainless steel, W.St.Nr. 1.4571 V4a |

| Cold water piping | Stainless steel, W.St.Nr. 1.4301 |

| Curtains | Rubber white, 3.0 mm thick |

| Sieving trays | Each 1 fixed screen (screwed) from perforated plate, hole diameter 5 mm, 2 changeover filters |

| Cover | Cooking zone isolated and lying in the water with hoist gear |

| Water level | Adjustable in the cooking zone by electrode control. Additional level control and magnetic valve for water supplementation |

| Insulation | Cooking zone and bottom lateral insulated and covered with stainless steel |

| Cooling | Plate cooler (Bandelot) and onsite refrigerating system |

Control

| Stainless steel switchboard completely wired. | |

| Control elements Kloeckner Moeller | |

| FI – Fa. SEW | |

| Switchboard type Rittal stainless steel incl. ventilator | |

| Flash light (built up) | |

| Heating control Bälz | |

| Program control Siemens S 7 with OP |

Cooking tunnel for Kupfer

Company Kupfer has got a Cooking tunnel for brewing sausages and different kind of sausages (wool sausages etc.)....

Read More...