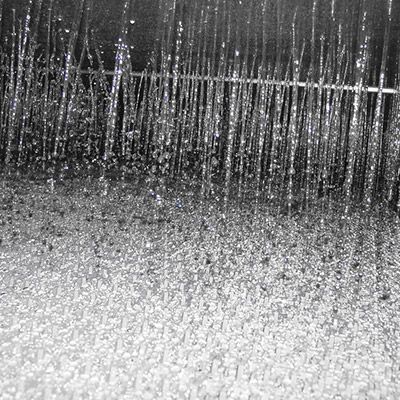

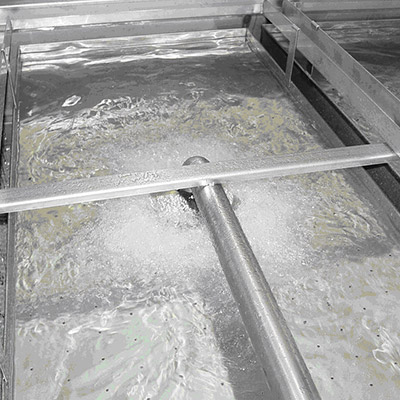

The pasteurizer with overspraying has the simple but also very good effect that pasteurizing and cooling are used instead of the normally used hollow cone spraying nozzles now so-called rinser plates which catch the water up to a certain height and then release through the holes in the floor area.

The principle is similar to that of a rainwater shower. Small water filaments pass from the top downwards over the containers and ensure that the product is evenly pasteurized with hot and cold water.

A further advantage of this system is that when the soiling / contamination in the water is used, the rinsing sheets can be easily cleaned from the outside and, if necessary, removed.

This does not result in dead spaces concerning water / transfer hot / cold. The small disadvantage in this case is that it is very expensive to construct and correspondingly more expensive than conventional nozzle sets

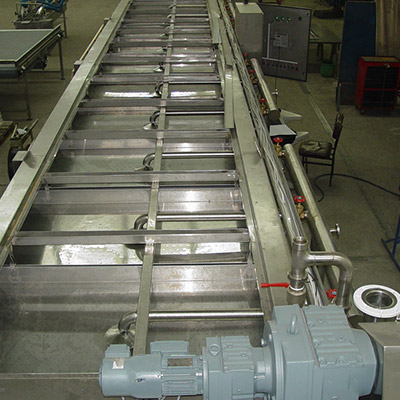

Construction

The containers are fed to the pasteurizer via the inlet conveyor in the drainage process. In the pre-treatment zone, water is sprayed with water from the "hot cooling zone" in the circulation process. The pasteurizing zone and cooling zone are each operated with tubs with perforation for overflowing with hot and then cold water.

At the inlet and outlet transfer ridegs are placed to transfer the package to the main conveyor belt (plastic module belt). The pre spraying zone is fed with water from the warmest cooling zone.

In the pasteurizing zone a so called foot bath is possible. By lowering the module chain in this zone as well as variably adjustable water level.

Specifications

| Type | Hot water and cold water overflow with foot bath |

| Performance | 720 ml glass, Ø 96 mm, pre-heating time of ~ 1 min, pasteurizing time of ~ 33 min., cooling time ~ 22.5 min. |

| Container Size |

Dimensions

| Total length | ~ 31.600 mm |

| Total width | ~ 3.450 mm |

| Tub length | ~ 30.000 mm |

| Tub width | |

| Net width | ~ 3.000 mm |

| Height | |

| Working height | ~ 1.000 mm, ± 50mm |

| Usable area in the pasteurizer |

Drives

| Main drive | Gear drive with frequency converter, 230/400 V, 50 Hz, IP 65, 0,18 kW. |

| Drive infeed belt | 1 Gear drive 0,55 kW mit FU |

| Drive output belt | 1 Gear drive 0,55 kW mit FU |

| Hot water pumps | 2 pcs stainless steel pumps 80-160/110, 11 kW |

| Cold water pumps | 3 pcs stainless steel pumps 50-125/30, 5,5 kW |

Material strengths and qualities

| Tub | Stainless steel, W.St.Nr. 1.4301, 3,0 mm |

| Cover | Stainless steel,, W.St.Nr. 1.4301, 1,5 mm |

| Sieving tray | Stainless steel, W.St.Nr. 1.4301, 2,5 mm |

| Frame | Stainless steel, W.St.Nr. 1.4301, 3,0 mm |

| Covers | Stainless steel, W.Str. 1.4301, 1,5 mm |

| Transport chain | Plastic module belt strong series |

| Hot water piping | Stainless steel, W.St.Nr. 1.4571 V4a |

| Cold water piping | Stainless steel, W.St.Nr. 1.4571 V4a |

| Hot water overflow | PA (spraying nozzles) Fabr. Lechler „Blue“ |

| Nozzles cold water zone | PA (spraying nozzles) Fabr. Lechler „Black“ |

| Curtains | Silicone rubber white, 4,0 mm thick (FDA quality) |

| Sieving tray | 2 changeover filters |

| Inlet conveyer 1-lane (190 mm) | ~ 5.000 mm long |

| Outlet conveyer 3-lane (3 x 114 mm) | ~ 5.000 mm long |

| Cover | Pasteurizing zone and cooling zone with criss-cross bend and handles loosely in the water tank |

Heating

| 2 pieces external pipe heat exchanger (lying) made of stainless steel W.St. 1.4571 / 1.4301. Incl. Footboard and insulation on the long side. Operating pressure max. 10 bar | |

| Steam & Condensation connection | |

| Control | 2 pcs. Bälz motor valve with control unit (3-step control), 2 pieces float condenser emptier |

| Temperature control | 2 pcs Pt 100 |

Cooling

| Fresh water supply with thermostat and solenoid valve | |

| Cooling medium | Fresh water (about 12 ° C) |

Control

| Stainless steel switchboard completely wired. | |

| PLC System | |

| Other controls Siemens/EATON | |

| S7-200SP including visualization | |

| Touchpanel 7“ "with serial. Interface | |

| Cabinet type Rittal stainless steel incl. forced air fan | |

| Flashlight (built up) | |

| Heating control via panel | |

| Incl. potential-free contacts and interface | |

| Temperature monitoring | |

| Level control | |

| Speed control main band |

Pasteurizers for Meiko

Company Meiko has received 2 new pasteurizers from ten Brink. 1 piece with a length of 30 meters...

Read More...