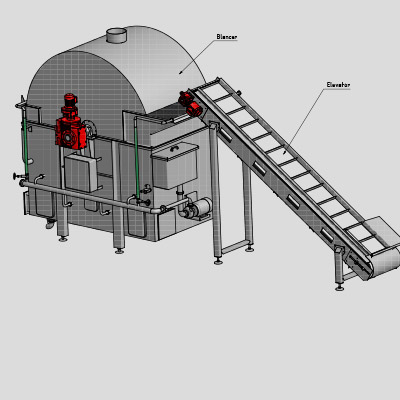

The blade wheel blancher is particularly suitable for short periods of blanching. The product is forced into this plant and has only the possibility at the outlet again in the same place in the same quantity and texture to come out. The effort is in the design of the plant. This can be customized according to customer requirements.

Construction

The plant is suitable for pre-blanching cucumbers and pepperoni (or similar piece products).Temperature control variable up to approx. 90 ° C.

The so called blade wheel blancher consists of a self-supporting tub construction with an integrated rotor (partly perforated plate). An external pipe heat exchanger (including motor valve and condensate emptier) is positioned next to the system as a heating system. Water circulation by circulation pump (V2a) incl. filter box with alternating sieves and water level level probes. On both sides large cleaning doors. Stainless steel switchboard is completely wired and ready to be connected.

Specifications

| Type | ZBL 1500 |

| Performance | ~6,000 Kg / hour with 5 minutes blanching time |

Dimensions

| Total length | ~ 2.300 mm |

| Total width | ~ 1.500 mm |

| Total height | ~ 1.900 mm |

| Inlet height | ~ 1.700 mm |

| Outlet height | ~ 1.050 mm |

| Drum diameter/td> | ~ 1.500 mm |

| Drum length | ~ 4.600 mm |

Drives

| Drum | SEW geared motor with frequency converter 0,75 kW |

| Inlet screw conveyer | SEW geared motor with frequency converter 1,1 kW |

| Outlet screw conveyer | SEW geared motor with frequency converter 1,1 kW |

| Circulation pump pickle | Stainless steel pump 5,5 kW |

Material strengths and qualities

| Completely made of stainless steel W.St. 1.4301 ex. drive |

Heating

| Indirect heating by pipe heat exchanger | |

| Performance | ca. 1.000 kW |

| Material | stainless steel V4a (1.4571) including insulation |

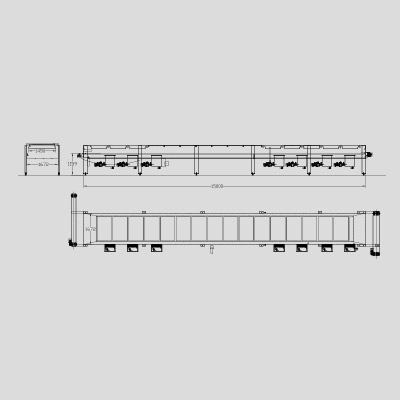

Pasteurizers for Meiko

Company Meiko has received 2 new pasteurizers from ten Brink. 1 piece with a length of 30 meters...

Read More...